Philanto Wellness Has Emerged As One Of India’s Most Esteemed Pharmaceutical Companies, And We Take Immense Pride In Our Contribution To Better Health And Improved Lives.

Get In Touch

+91 9996103333

info@philantowellness.com

PLOT NO. 14,ARJUN NAGAR,NANHERA AMBALA CANTT., HARYANA

Third Party Pharma Manufacturing in India: Launch Your Brand with Ease

Thinking of launching your pharma brand? Third party pharma manufacturing (also known as contract manufacturing or private-label production) allows you to manufacture medicines under your label, without the need to build a factory. In this approach, you partner with an established plant that produces products (such as tablets, syrups, and ointments) for you. This means small companies and startups in India can create their products quickly and affordably. Your chosen manufacturer handles the formulation, production and packaging, while you focus on branding and sales.

Download Approval List

- Big savings & scalability: Producing in bulk cuts your per-unit costs, boosting profit. Large orders mean lower material and manufacturing costs, thanks to economies of scale.

- Low investment: You avoid the huge expense of buying machines or setting up a plant. Many contract manufacturers offer low minimum orders and startup costs (for example, one firm notes ₹15–20K vs ₹50–60K elsewhere ), so you can launch with a small investment and still enjoy healthy margins.

- Global reach: Once products are made, you can sell them anywhere; there are no geographic limits. This lets your brand expand nationally or internationally without extra capital.

- Expert quality & compliance: Experienced scientists and certified labs back the process. Good manufacturers are WHO-GMP and GLP certified, meaning they follow top global standards. Every batch is thoroughly tested in-house, so your products match the quality of big pharma names.

- Your brand, your design: Unlike franchises, contract manufacturing puts your logo on the pack. Many companies even have in-house design and packaging teams to create professional labels and boxes for you.

- No dead stock: You pay only for the batch you order. The whole batch is billed to you, so there’s no leftover inventory to expire. This means every product made becomes immediate revenue.

- Focus on core business: With manufacturing handled externally, you can focus on marketing and growing your business. Experts note that outsourcing frees up resources and improves cash flow. You avoid production hassles and concentrate on selling your brand.

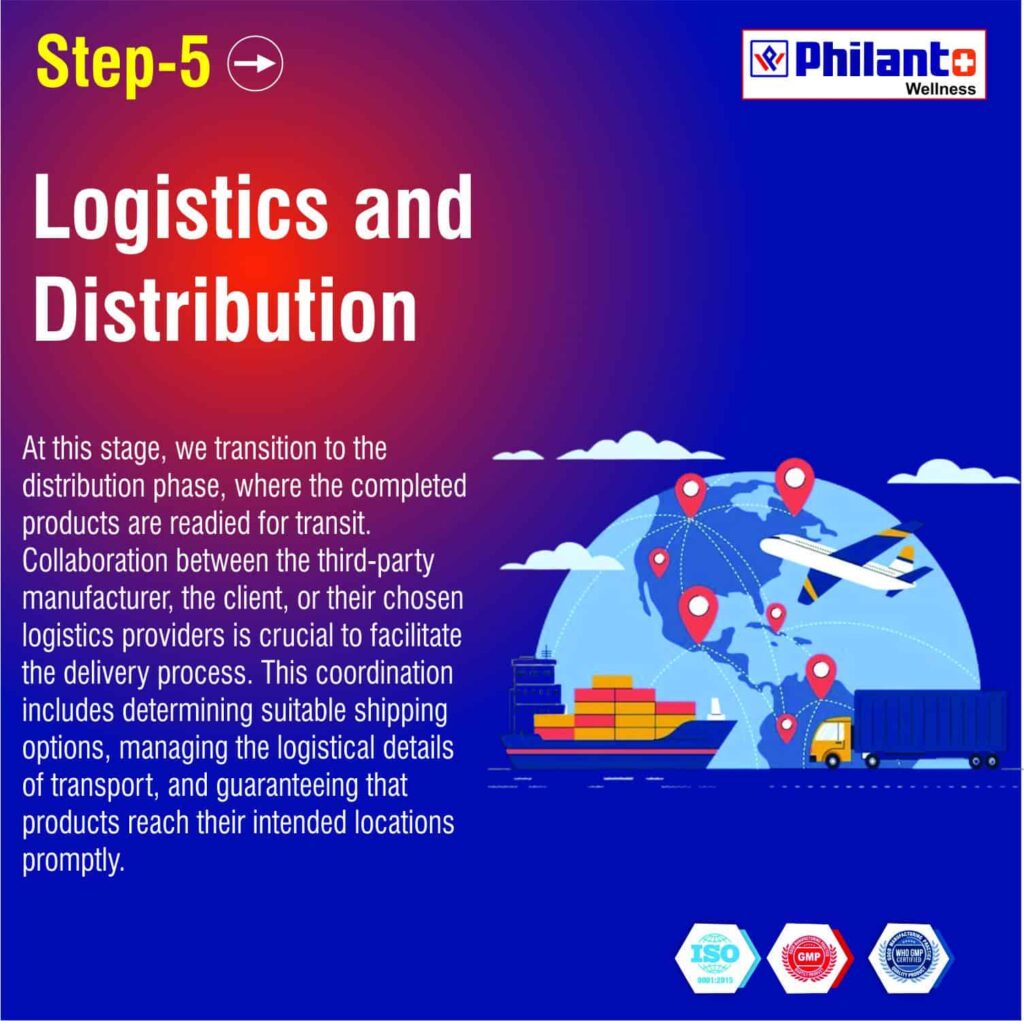

How It Works: The Pharma Manufacturing Process

In practice, third party manufacturing breaks down into clear steps. For example, Philanto Wellness outlines a typical timeline of about 35–40 days for a new product (around 25–30 days if it’s a repeat formulation). Key phases include:

- Regulatory approvals: Obtain formulation approvals from the state or central drug authority (≈5 days)

- Design & packaging: Finalize your product design and send packaging materials for printing (≈5 days)

- Raw material procurement: The manufacturer sources the active ingredients and excipients (≈10 days)

- Production & quality testing: Manufacture the product in the plant and test its quality in parallel (≈12–15 days)

- Packaging & shipping: Finally, the finished products are packed and shipped to you with all quality documentation (≈5–7 days)

In practice, launching a new product usually takes about a month from start to finish. Many third party pharmaceutical firms can work with tight lead times (around 20–30 days for delivery ), helping you reach the market quickly.

They also handle packaging and labelling according to your brand’s design (some even have in-house design teams), so your products arrive fully branded and ready to sell

Quality & Certifications

Quality is crucial in pharma. Reputable Pharma Contract Manufacturers hold WHO-GMP and GLP certifications, meaning they follow strict international production standards.

Their laboratories are staffed by trained scientists who rigorously test every batch. By choosing a WHO-GMP certified partner, you ensure your products match the quality of leading brands. The manufacturer’s expertise and facilities (from sterile production lines to quality control labs) give you confidence that each batch is safe, effective and up to regulatory norms.

Why Choose Third Party Pharma Manufacturing?

Third party Pharmaceutical manufacturing brings together professional facilities with minimal risk to you. You don’t need to invest in machinery or worry about technical staffing;

The manufacturer covers all that. Instead, you benefit from their infrastructure and experience. For instance, a good contract partner will procure raw materials from reliable vendors and use well-calibrated machines (as outlined by providers like Philanto Wellness), ensuring your products are of high quality.

Because the entire batch is produced for your order, you avoid inventory waste. This “zero dead stock” approach means every unit made is yours to sell, boosting your revenue. With the factory running smoothly, you can focus on growing your business: marketing your products, expanding distribution, and building your brand. Many pharma companies have found that the cost savings from outsourcing (not having to run their plant) far outweigh the fees paid to a pharma contract manufacturer, allowing them to reinvest in R&D or promotion

Documentation Submission for Third Party Pharma Manufacturing

Our firm upholds a high standard of professionalism within the realm of Third Party Pharma Manufacturing services. To collaborate with us, prospective partners are required to provide the necessary documents as follows:

- A fully detailed, signed, and verified Contract Manufacturing Agreement

- Certificate of Non-resemblance

- Address of the Marketing or Corporate Office

- Company profile, including authenticated signatures of directors or partners, and accompanying documents (Aadhar Card and Pan Card)

- Resolution Copy for Authorised Signatory Representation

- Valid Drug License

- Applicable Sales Tax/TIN or GST Registration Certificates/Number

- Company’s Logo and a depiction of Brand Values (if applicable)

- Preferred Tonality and Design Schemes (if applicable)

Partner with India’sTop Third Party Pharmaceutical Manufacturer

Philanto Wellness stands as a beacon of excellence in the Indian pharmaceutical landscape, producing superior-quality products from manufacturing facilities certified by GMP-WHO. With over 100+ associates relying on our manufacturing prowess, we specialise in bulk order production, which significantly lowers both production costs and labour expenses. Below are the key attributes that define Philanto Wellness as a third party manufacturing in pharma partner:

- State-of-the-Art Equipment: At Philanto Wellness, our manufacturing units are not only approved by GMP-WHO standards but are also outfitted with cutting-edge technology to ensure we stay at the forefront of pharmaceutical innovations.

- Efficient Operational Services: We, at Philanto Wellness, provide comprehensive services that include punctual delivery, effective sales strategies, and robust marketing support for our products. Our Third Party Manufacturing services are designed to provide ample room for our partners to concentrate on amplifying their marketing strategies with innovative ideas.

- Global Recognition: Our meticulous attention to every detail of the manufacturing process at Philanto Wellness enables our products to receive accolades and recognition on an international scale, enhancing our global presence.

- Cultivate Your Business with Affordable Investment: Philanto Wellness offers you the golden chance to expand your business with minimal investment, ensuring that we deliver top-notch products that contribute significantly to your company’s growth and success.

Why Choose Philanto Wellness for Third Party Pharma Manufacturing

As a WHO-GMP certified company, Philanto Wellness stands out as a trusted partner in the pharmaceutical manufacturing industry. Here’s why you should consider partnering with us:

Proven Track Record: With a history of excellence and a track record of delivering top-quality products, Philanto Wellness is a name you can trust.

Cutting-Edge Facilities: Our state-of-the-art manufacturing facilities are equipped with the latest technology and adhere to the most stringent quality standards.

Experienced Team: Our team of experienced professionals is dedicated to ensuring the success of your pharmaceutical products.

Customized Solutions: We offer tailored solutions to meet your specific needs, from formulation development to packaging and distribution.

Global Reach: Philanto Wellness has a global reach, allowing you to expand your market presence with ease.

customers reviews

Amit Verma

Working with Philanto Wellness has been a game-changer for our brand. Their third-party manufacturing service is top-notch — from timely delivery to premium product quality, everything was seamless. Highly recommend them for anyone looking to outsource pharma production

Sneha Patil

We’ve partnered with several manufacturers over the years, but none have matched the professionalism and quality of Philanto Wellness. Their WHO-GMP certified facilities and transparent process gave us complete peace of mind.

Rohit Sharma

The team at Philanto Wellness is extremely responsive and reliable. Their third party manufacturing services helped us launch our product line faster than expected, without compromising on quality or compliance.

Pooja Mehta

We’ve been manufacturing tablets and capsules through Philanto Wellness for over a year now. Their attention to detail, quality control, and packaging standards are truly impressive. Great long-term partner!

Dr. Karan Malhotra

Philanto Wellness has helped our pharma brand scale effortlessly. Their third-party manufacturing service is cost-effective, dependable, and handled by a highly professional team. Couldn’t have asked for a better partner.

Third Party Pharma Manufacturing FAQ's

We strive to accommodate varied business needs and can discuss minimum order quantities on a case-by-case basis.

Absolutely. We are committed to supporting products that promote natural well-being and can tailor our third party manufacturing to produce organic lines that meet industry certifications.

Yes, by utilizing the ready-to-use infrastructure and expertise of third-party manufacturers, companies can reduce production lead times.

Yes, we offer comprehensive packaging and labeling services that adhere to regulatory requirements while also reflecting the essence of your brand.

Absolutely, our end-to-end branding solutions include logo design, thematic packaging artwork, and the creation of promotional materials.

We ensure excellence through meticulous process management, expert formulation, and precise quantities of raw materials and packaging, resulting in products that meet and surpass global standards.

With partnerships extending to over 500 companies, we have cemented ourselves as a dependable entity in the market.

We take pride in our impressive collection of over 1000 product approvals, spanning diverse market segments and therapeutic formulations, tailored for both manufacturing and marketing endeavors.

Quality assurance is paramount, with an in-house advanced laboratory setup complemented by collaborations with leading external laboratories for routine, stringent testing.

Philanto Wellness offers full-scale formulation services, from initial concept to final product development, incorporating a holistic approach to wellness in every step

Our commitment to excellence is reflected in our prestigious certifications, which include ISO, WHO, GMP, HACCP, and GLP, ensuring adherence to global quality standards.

We strive to fulfill orders within a lead time of 20-40 days, offering a flexible MOQ based on your brand requirements and ambitions.

Embarking on your branding journey necessitates the provision of certain documents, such as incorporation certificates, PAN, trademark/IP certificates, MSME, Aadhaar, GST, and a drug license.

Our manufacturing prowess is bolstered by cutting-edge German Glatt machinery and Swiss Waters HPLCs, ensuring your products meet the highest quality benchmarks.

Investment levels vary depending on several factors such as product complexity, ingredients, order volume, and specific client requirements. We offer a structured pricing model and are happy to provide a detailed quote following an initial consultation to discuss your specific needs and goals.

Our global client base spans more than 10 countries, reflecting the international trust and reliance on Lifecare Neuro’s offerings.

At Philanto Wellness, we harness the talents of a 400-strong workforce, each member bringing specialized knowledge and skill in the pharmaceutical arena to deliver superior drug formulations.

Philanto Wellnes portfolio features a trio of product lines— tablets, capsules, Ointment , and Liquid Section each customizable in packaging and size to your specifications.

Become A Business Partner

Get Pharma Update

Join over 6,000 people getting our emails